Project snapshot

Alignment with RDA strategy

- Economic development

Alignment with RDA strategy

- Economic development

Grant Recipient Case Study – 2024 Funding Round

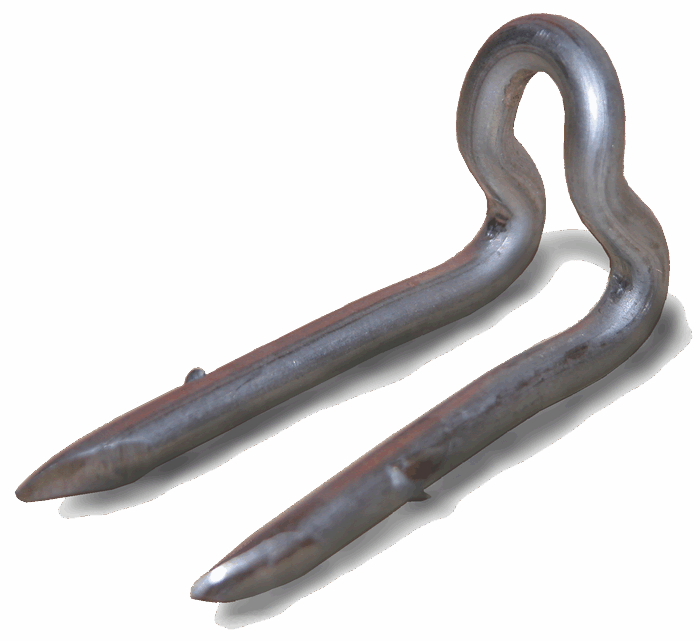

Niche manufacturer, Tuckaway Engineering, designs and manufactures the Tuckaway™ Staple system, a specialised trellis fastening solution used in vineyards across Australia.

With seasonal market shifts and increasing pressure to reduce costs, the business identified a range of efficiency upgrades that could help reduce labour, improve safety, and prepare for long-term growth.

Building a more efficient production process

The grant supported a suite of upgrades across Tuckaway’s operations, each aimed at tackling a different productivity bottleneck. Key purchases included:

- Forklift slipper extensions and a replacement battery, to improve transport and loading

- A solar battery charger, to ensure reliable forklift availability

- A pneumatic clipper machine, to automate elastic loop assembly

- Bespoke staple machine components and updated PLCs (programmable logic controllers)

Each upgrade addressed a different productivity challenge, from manual strain and OH&S risks to inconsistent production outcomes.

How the grant funding was used

With the forklift upgrades, Tuckaway reduced loading time from 20 minutes of manual labour to just 1–2 minutes per pallet. Forklift start issues have dropped to zero, and overall morale has improved with less manual handling required.

Meanwhile, the introduction of a mechanical clipper cut the time to create elastic loops from more than 30 seconds each to just 5 seconds, making the process faster, more reliable, and less dependent on skilled labour.

Though some custom components are still in development, their expected delivery and testing is projected to unlock further gains in staple production.

What has happened since receiving the grant

Despite industry-wide downturns affecting the wine grape sector, Tuckaway Engineering was able to move ahead with long-term productivity investments thanks to the grant. While some components are still rolling out, the early gains have already delivered tangible improvements in speed, consistency, and staff satisfaction.

As conditions stabilise, the business is now well positioned to scale operations and respond more flexibly to customer demand.

Feedback on the Hills & Coast grant process

Trista Badger, Tuckaway Engineering

“The grant encouraged us to devote time, focus and energy to identifying concrete productivity improvement measures, and to plan coherently for future growth.

It was an encouraging and meaningful boost to our business development activities, and made an appreciable difference. Many thanks!”