Project snapshot

Region

Fleurieu Peninsula

Project contact

Steve Shotton

Regional Development Manager

Alignment with RDA strategy

- Economic development

Region

Fleurieu Peninsula

Project contact

Steve Shotton

Regional Development Manager

Alignment with RDA strategy

- Economic development

Grant Recipient Case Study – 2022 Funding Round

Matchett Productions & Big Sissy Foods, based on the Fleurieu Peninsula, are renown for local produce made from local ingredients, that encompass a range of award-winning, hand-crafted products.

Owner, Vicki Matchett, established the business more than 30 years ago with a strong commitment to community, environment, and high-quality products, which is evident across her product line that includes condiments, dukkah, quince paste, olive products and artisan sourdough bagels & bagel crisps.

A recipe for greater efficiency

With growing appetite for their products, Matchett Productions have needed to increase output to keep pace with demand. However, to date their hand-crafted wares have also involved labour-intensive hand-filling processes.

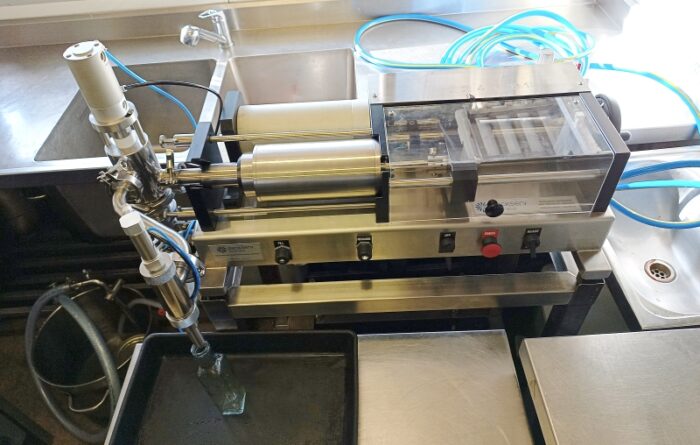

Vicki and her Business Development and Sales Strategist, Fiona Watson, recognised the need to streamline their operations, improve efficiency and address potential OH&S issues from hand-filling bottles and jars. This provided a catalyst for the business to investigate acquisition of an Asset Volumetric Filling Machine which could be set to quickly fill each jar or bottle with the exact volumes required for each product.

By automating this production step, Vicki and Fiona anticipated time savings of up to 50% to package their products, greater filling precision for less product wastage, reduced risk of workplace injury, and expanded capacity to create more products for sale.

How the grant funding was used

The Hills & Coast Business Grant funding allowed Matchett Productions to fast-track purchase of the Asset Volumetric Filling Machine by covering a significant portion of the purchase cost. The machine was adapted to their specifications, with consideration for the variety of products they would need to run through it, from lighter dressings and vinegars, to heavier sauces and jams.

What has happened since receiving the grant

As with many complex machines, there were some teething problems with getting the filling machine up and running. An additional piece of joinery had to be engineered for their needs and, after initial testing, it was thought a different cylinder size might be required to overcome an issue with air pockets in the lines. This meant the equipment had to be taken off-site for adjustments, leading to delays in full implementation of the machine.

However, the early results are promising and with the preliminary glitches addressed, Vicki and Fiona are considering adding an automatic conveyor belt and assembly table to further streamline and speed up production.

Feedback on the Hills & Coast grant process

Fiona and Vicki completed the grant application together. Vicki looked after supply of the relevant financial details, while Fiona put the submission together, saying a previous Grant Writing Workshop she had attended was invaluable in both finding and completing suitable grants.

They found the Hills & Coast Business Grant was made easy, from research to submission, with clear requirements and prompt payment of funds.

The Hills & Coast Business Grant has been exponential in planning for the future growth of our business. We are confident it will assist us in taking the business to another level, both professionally and financially. We would encourage any small business to invest the time in applying for the RDA grant, as it has provided crucial funding toward a key piece of equipment that otherwise may not have been attainable.

Fiona Watson, Business Development and Sales Strategist, Matchett Productions